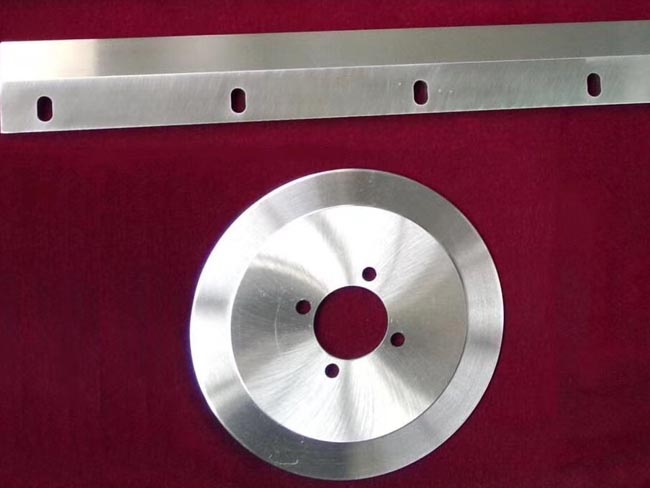

PCB Depanelizer Blades

Apr 27 , 2021PCB Depanelizer Blades

The deadline of PCB depanelizer blade is closely related to the material of blade. Good material will last a long time, but the price is undoubtedly expensive, and it is also related to the raw material of PCB boards. During the period when the PCB depaneler stops working, the staff should pay attention to the maintenance work, pay attention to the maintenance of the left and right knife positioning plates and the left and right cutting edges anytime and anywhere, remove the surface and internal debris of the equipment, and check the tightening condition of the equipment screws anytime and anywhere. If the equipment does not work for a long time, the left and right positioning plates should be removed. The left and right cutting tools should be oiled to maintain them. They can be wiped down before using it. In addition, before using PCB depaneler, it is necessary to check whether the power supply circuit is damaged.

The PCB depanelizer is driven by stepper motor, which can be clamped tightly. After inserting wires, it can be accurately laser cut and positioned. PCB depaneler solves the difficulty of changing the four stroke point of Brushless DC motor and AC motor due to inertia torque after a period of working. The laser cutting schedule interval of PCB splitter is adjusted according to the three touch control sections, which can quickly change the specifications and models of different printed circuit boards. The schedule of NC cutting tools is 400mm (600mm can be customized), and the available PCB width of traditional mechanical equipment is less than 600mm.