There are three types of curve PCB separators for routed PCB boards:

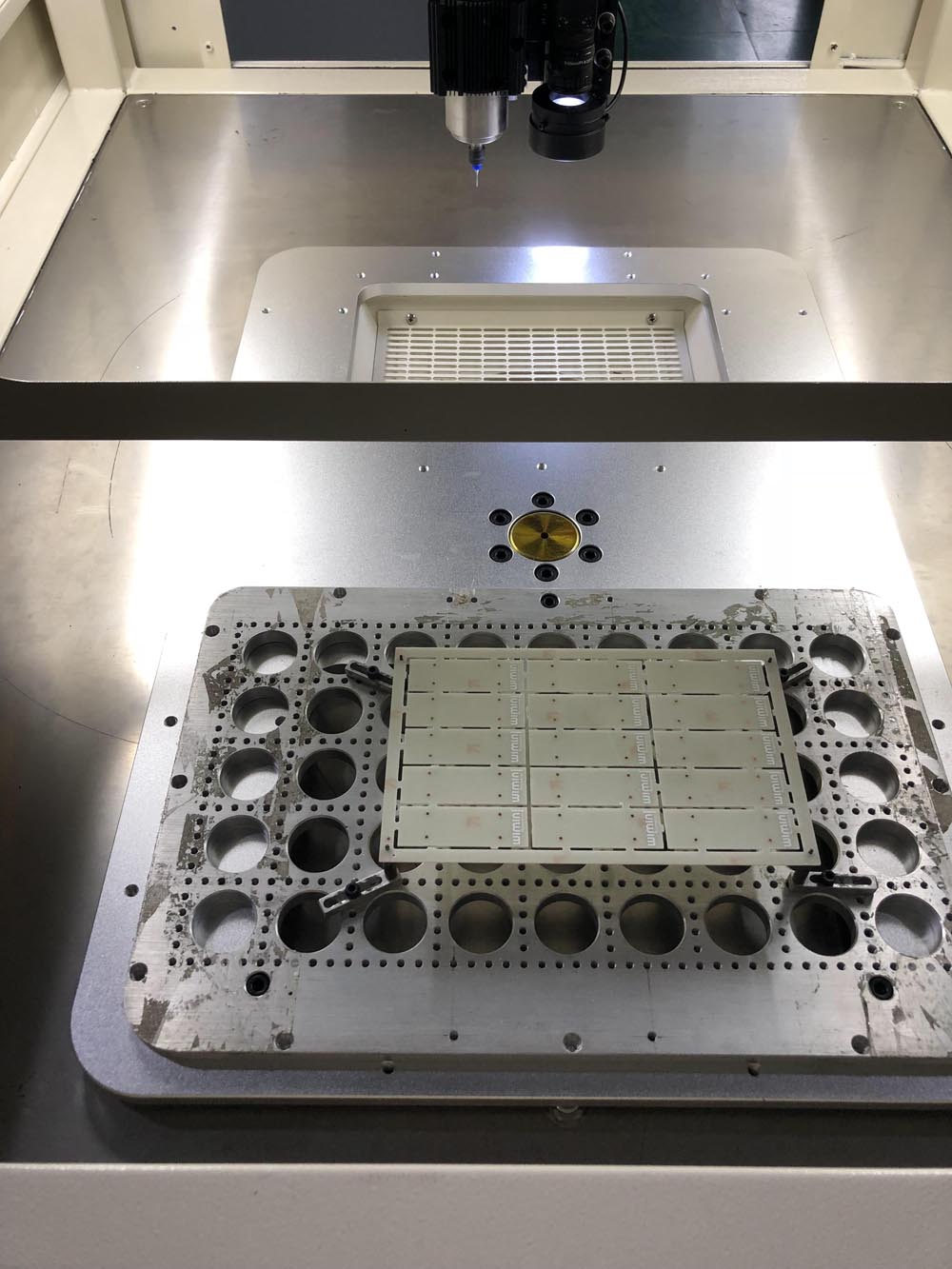

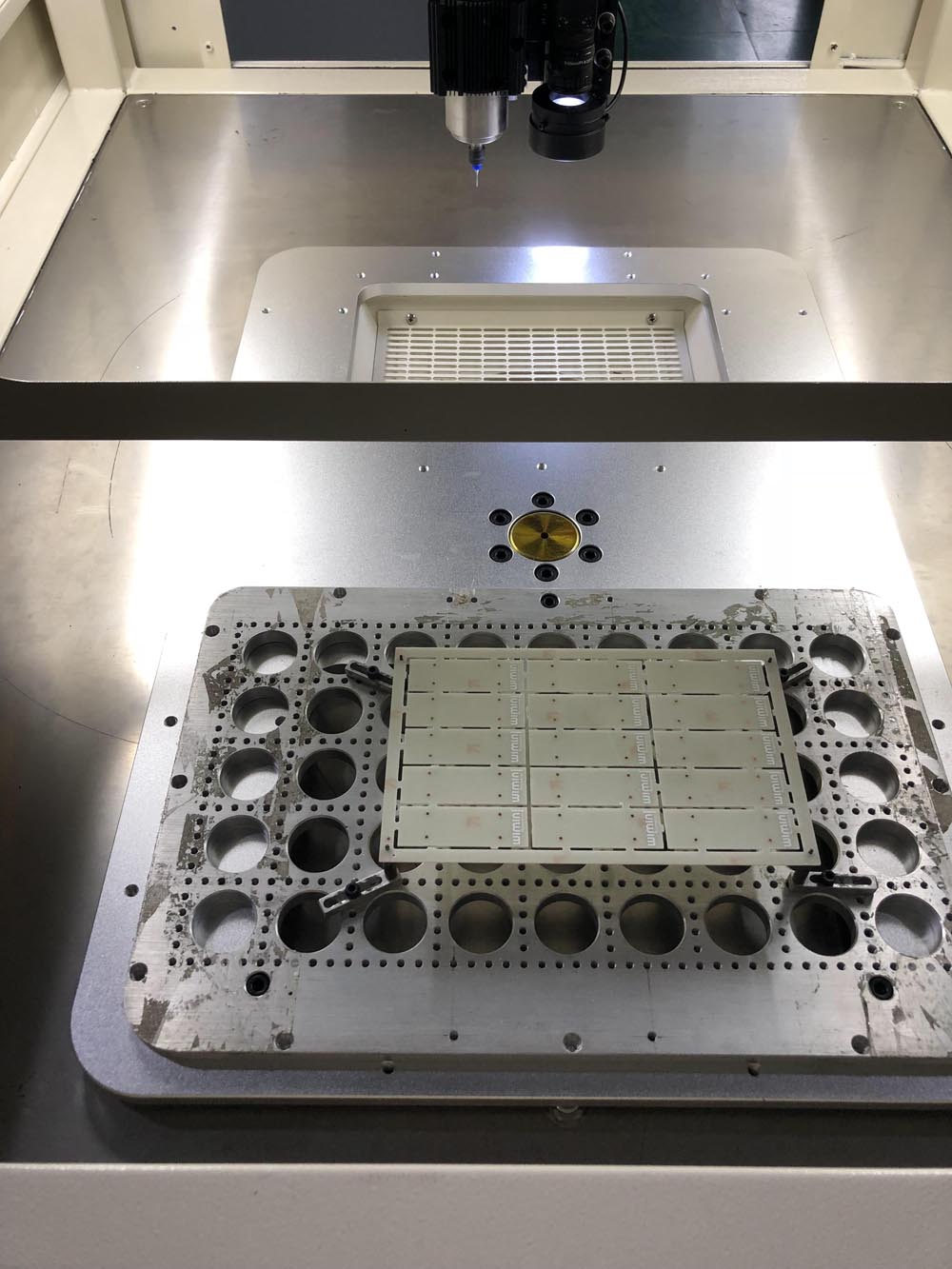

1. First, it is the type of milling cutter automatic PCB router machine, which is suitable for segmentation and semi-finished products. Small cutting machine can be produced online, with fast cutting speed, high precision and simple operation. You can start production by exchanging fixtures. Use high-intensity dust collection system to keep PCB and working surface clean.

PCB size 460mm x 410mm

X y cutting speed 0 ~ 100mm / S

Machine accuracy ± 0.01mm

Z-axis stroke 60mm

Board and manual editor are adopted for y and Z control modes

Y, Z drive mode Korean stepping servo motor

Cutting accuracy ± 0.1mm

Spindle speed max 60000rpm

Host voltage 220V 50 / 60Hz

Power consumption 1kVA

Dust collector mode: bottom cleaner

Vacuum cleaner voltage 380V 3p

2. PCB Nibbler:

1. Full pneumatic control, simple operation

2. Suitable for cutting various PCB connection points

3. Hook type work, and the shape of hook can be customized

4. It is convenient and fast to replace the hook knife

5. Small size, no damage to the base plate and parts on the base plate

Machine size 280x105x185mm

Number of strokes 12 times / min

Working pressure 0.50-0.70mpa dry air source

Slider stroke 2mm

Machine weight: 20kg

3. Punch type Manual Feeding PCB Punching Machine:

The structure design is compact, super hard, easy to operate and safe to use.

It is necessary to change the mold according to different products, which is convenient and simple.

The lower mold enters and exits automatically, which is convenient for taking and placing products, and the finished products fall into the drawer.

Minimize the internal stress generated when cutting the circuit board and avoid tin cracking.

The efficiency of die cutting semi-finished PCB and FPC is very high.