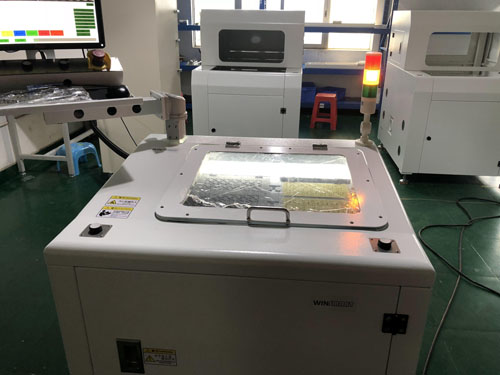

Optional Single / Dual Table Semi-auto PCB Depaneling Router Machine

Oct 08 , 2021

SMTR17 PCB depaneling router is a kind of equipment which mainly uses milling cutter running at high speed to separate multi connected PCB according to pre editing path. It can replace manual breaking or cutting defects of c-cut or push, improve product quality and reduce scrap rate. This machine adopts latest operating system with man-machine interface. The cutting path can be modified by high pixel CCD teaching and editing, and it can also be modified step by step. Using the rotating platform as the loading and unloading device of PCB, the idle time of the machine can be effectively reduced, and the ideal production efficiency can be achieved.

1. Equipped with high pixel color CCD magnifying lens, auxiliary program teaching and editing simulation function, more accurate precision and clearer image.

2. Tool life monitoring: after cutting a certain distance, the milling cutter will automatically rise / fall to the position of the cutting edge which has not been cut. The up and down distance and times can be set freely according to the length of the cutting edge, so as to prolong the life of the milling cutter.

3. The transparent safety door design makes the processing process clear at a glance. The door opens and stops to prevent accidents during processing, providing a safe operating environment for users

4. Automatic mark positioning and correction system, moving path display and tracking, automatic focus correction function, higher cutting accuracy.

5. Three same or different programs can be used on the same fixture to locate by mark, so as to ensure the cutting accuracy

6. Powerful dust collector can clean and solve the problem of cutting dust. The imported fan makes the dust collection more clean and low noise.

7. Use the left and right worktable to exchange processing and place PCB substrate, reduce waiting time and increase production capacity.

8. In general, the semi-auto PCB router machine is electrical, and the worktable is pneumatic. If it works for a long time, the PCBA may be damaged due to insufficient air pressure. The machine is completely powered on, so as to ensure its accuracy and stability.

Machine Installation:

1. Place the dual table PCB router machine in the designated position.

2. Adjust the level of the equipment with a level instrument, and then tighten the foot cup screw.

3. Connect the hose of the dust collector to the dust collecting port of the equipment.

4. Connect the power plug of the dust collector with the equipment to confirm the operation direction and dust collection effect. If it is reversed, replace any two of the three power lines.

5. Grounding requirements: please connect the equipment to the ground wire of distribution box separately, and do not connect with other equipment in series.

Power supply configuration

1. The standard input of the equipment is single-phase 220 V AC.

2. The equipment input 3-phase 380V AC needs to be equipped with transformer.