PCB Punch machine, FPC Punching machine, stamping holes PCB punch machine principle and application:

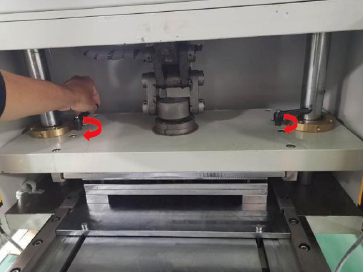

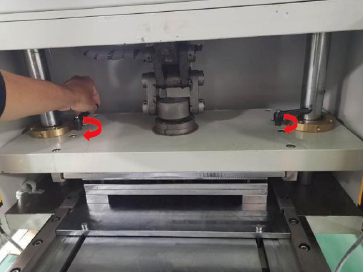

Install the

PCB punching machine die tooling on the mold location, put the FPC / PCB boards to be cut at the corresponding position of the lower die, and press the start switch to cut the boards at one time. During work, the lower die adopts automatic push-pull to reduce labor intensity and improve safety. At the same time, it is very convenient to take and place the separated boards.

Punch machine PCB separator, FPC punch, stamping holes PCB depanelizer application scope:

The circuit boards of mobile phones, digital cameras, electronic accessories, computers, automobiles, etc. can be die-cut in batch, and can give full play to the maximum effect when cutting multiple circuit boards. In the electronic industry, such as mobile phone board, memory card, mobile phone flexible circuit, HDI (high density printed circuit board), FPCB flexible circuit board (flexible circuit board) and FCCL (flexible copper clad laminate), the efficiency is particularly significant for the segmentation of large quantities of slotted PCB substrate and flexible circuit board (FPC).

Punch machine PCB separator, FPC punch, stamping holes PCB depanelizer features:

1. High degree of automation, simple and safe operation

2. Multiple molds can be replaced, and the mold replacement is convenient and easy

3. The lower mold enters and exits automatically, which is convenient for taking and placing products, and the finished products can fall into the drawer

4. Minimize the internal stress generated during plate cutting and avoid tin cracking

5. The efficiency of punching semi-finished PCB and FPC is very high

6. The latest new touch screen function is convenient for the operator to operate.